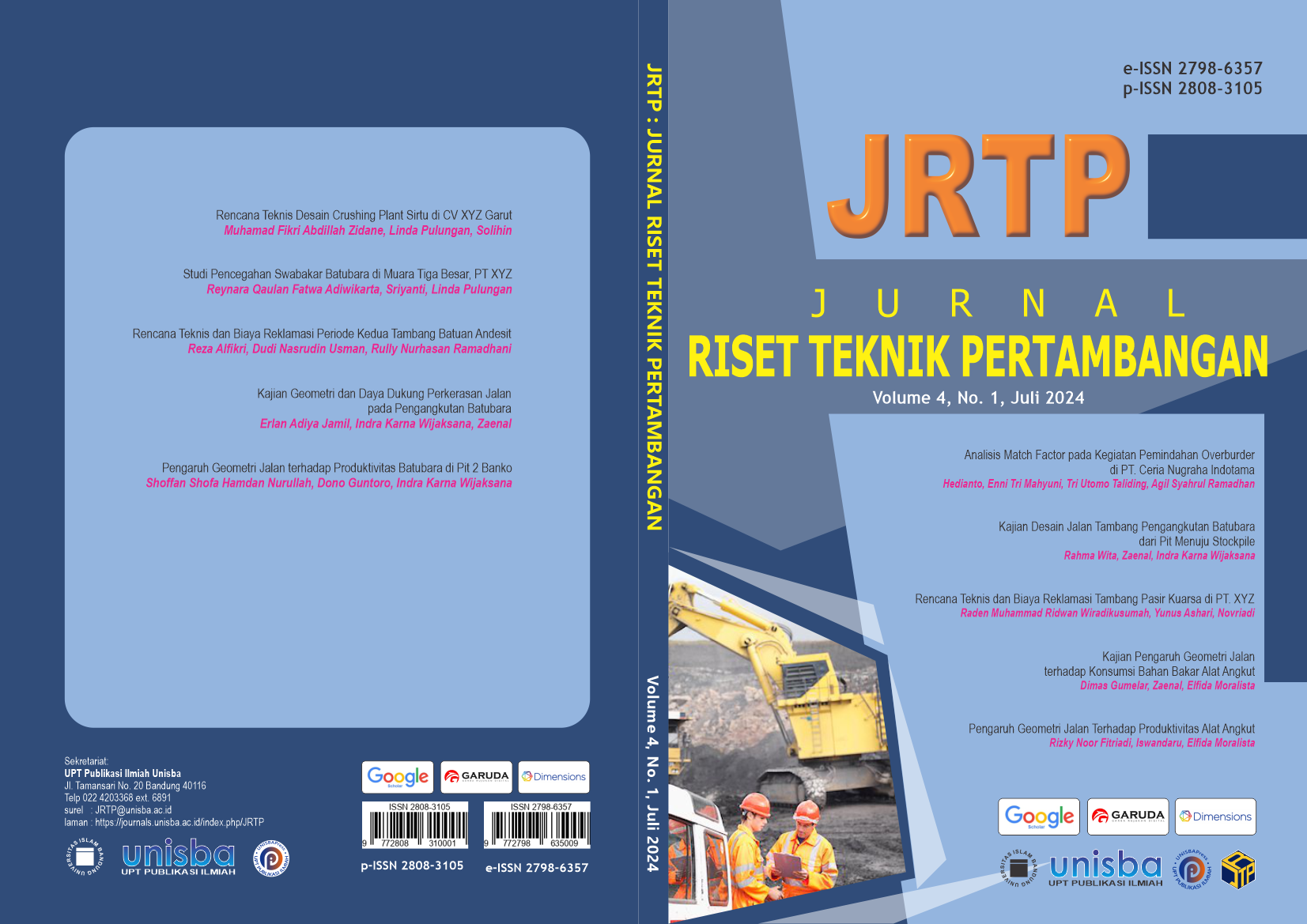

Rencana Teknis Desain Crushing Plant Sirtu di CV XYZ Garut

DOI:

https://doi.org/10.29313/jrtp.v4i1.3880Keywords:

Crushing Plant, Jaw Crusher, Cone CrusherAbstract

Abstract. CV. XYZ is a company engaged in the mining sector with gravel and sand commodities. The company is located in Margaluyu Village, Leles District, Garut Regency, West Java Province. To increase the quantity of sirtu from mining activities, CV. XYZ has designed a crushing plant with a production target of 120 tons/hour. The sirtu processing activities at CV. XYZ's crushing plant consist of five stages: feeding using a vibrating feeder, primary crushing with a jaw crusher, secondary crushing with a cone crusher, tertiary crushing with a cone crusher, and sizing using a vibrating screen. The crushing plant unit is also supported by auxiliary equipment such as hoppers and belt conveyors. The feed entering the process is 125 tons/hour with material size up to 500 mm, assuming that 95% of the material will be processed and 5% considered as impurities. The equipment used in the crushing plant includes one hopper with a capacity of 101.6 m³, one vibrating feeder ZSW600x130, one jaw crusher PE-600x900, one cone crusher PYB-1200, one cone crusher PYB-600, one vibrating screen 3YK1548, and seven belt conveyors. The final product is divided into three types: fraction 1 (-20+10 cm), fraction 2 (-10+5 cm), and stone dust (-0.5 cm), with a total production of 124.47 tons/hour. The design of the crushing plant successfully meets the production target of 120 tons/hour.

Abstrak. CV. XYZ merupakan perusahaan yang bergerak di bidang pertambangan dengan komoditas bahan galian sirtu, berlokasi di Desa Margaluyu, Kecamatan Leles, Kabupaten Garut, Jawa Barat. CV. XYZ merancang crushing plant dengan target produksi 120 ton/jam. Proses pengolahan sirtu di unit crushing plant terdiri dari lima tahapan: pengumpanan menggunakan vibrating feeder, primary crushing dengan jaw crusher, secondary crushing dengan cone crusher, tertiary crushing dengan cone crusher, dan sizing menggunakan vibrating screen. Unit ini juga didukung oleh alat penunjang seperti hopper dan belt conveyor. Feed yang masuk sebanyak 125 ton/jam dengan ukuran material 500 mm, dengan asumsi 95% material diolah dan 5% sebagai pengotor. Peralatan yang digunakan meliputi satu hopper dengan kapasitas 101,6 m³, satu vibrating feeder ZSW600x130, satu jaw crusher PE-600x900, satu cone crusher PYB-1200, satu cone crusher PYB-600, satu vibrating screen 3YK1548, dan tujuh belt conveyor. Produk akhir dibagi menjadi tiga jenis: fraksi 1 (-20+10 cm), fraksi 2 (-10+5 cm), dan abu batu (-0,5 cm), dengan total produksi mencapai 124,47 ton/jam. Hasil perancangan crushing plant ini berhasil memenuhi target produksi 120 ton/jam.

References

L. P. D. G. Danny P Mahendri, Evaluasi Kinerja Crushing Plant Batuan Andesit Dalam Upaya Meningkatkan Kapasitas Produksi di PT. Ansar Terang Crushindo, 1st ed., vol. 3. Bandung: Prosiding Teknik Pertambangan, Universitas Islam Bandung, 2017.

A. Riyanto, Bahan Galian Industri Edisi II. Bandung: Pusat Penelitian dan Pengembangan Teknologi Mineral (PPTM), 2000.

L. P. S. W. Ikhwanul Ihsan, Analisis Kinerja Belt Conveyor untuk Optimasi Produksi Batuan Andesit, 1st ed., vol. 5. Bandung: Prodi Teknik Pertambangan, Universitas Islam Bandung, 2019.

Ir. Partanto Prodjosumarto, Pemindahan Tanah Mekanis. Bandung: Jurusan Teknik Pertambangan, Institut Teknologi Bandung, 1993.

Anonim, Shanbao Product Brochure. Shanghai, China, 2019.

M. A. Supriatna S, Bahan Galian Industri. Bandung: Pusat Penelitian dan Pengembangan Teknologi Mineral (PPTM), 1997.

Anonim, Conveyor Belt Design Manual. Bridgestone Corporation. Tokyo, Japan, 2003.

L. P. S. Tubagus Maulana Alam Kusuma, Analisis Produksi Berdasarkan Kinerja Crushing Plant, 2nd ed., vol. 7. Bandung: Prosiding Teknik Pertambangan, Universitas Islam Bandung, 2021.

S. Z. Tubagus Hidayatullah, Evaluasi Kinerja Crushing Plant Batu Andesit PT.Widaka Indonesia, 2nd ed., vol. 2. Bandung: Prosiding Teknik Pertambangan, Universitas Islam Bandung, 2022.

Cahya. R.N, Kajian Kinerja Unit Crushing Plant Batu Andesit PT. Sumber Gunung Maju. Reaserchgate. Universitas Sriwijaya, 2020.

Yodi Kurniawan, Elfida Moralista, and Zaenal, “Penentuan Remaining Service Life Struktur Conveyor B pada Tambang Batubara PT XYZ,” Jurnal Riset Teknik Pertambangan, pp. 1–6, Jul. 2023, doi: 10.29313/jrtp.v3i1.786.