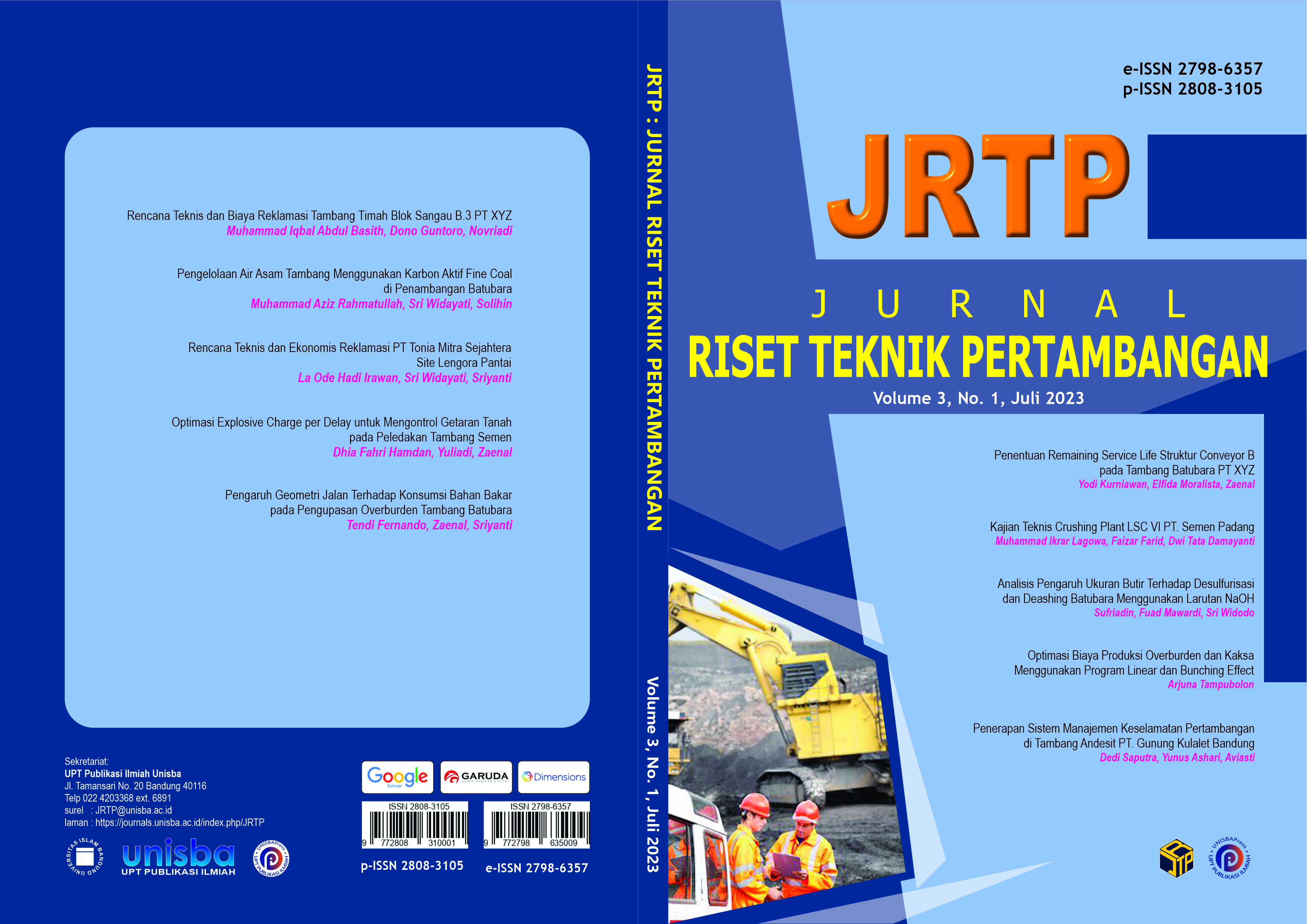

Kajian Teknis Crushing Plant LSC VI PT. Semen Padang

DOI:

https://doi.org/10.29313/jrtp.v3i1.1654Keywords:

Batu Gamping, Crushing Plant, Persentase OversizeAbstract

Abstract. Limestone is one of the main raw materials in the manufacture of cement. Limestone crushing using a crushing plant. The purpose of this study is to calculate the average value of Reduction Ratio and Work Input contained in the crushing plant, determine the effect of feed size on the percentage of oversize and electrical energy in the crushing plant, determine the effect of feed rate on the percentage of oversize and electrical energy power in the crushing plant. and analyze the crushing plant based on Ministerial Decree No. 1827 K/30/MEM/2018 in terms of 95% capacity and 15% oversize. The method used is descriptive to determine the value of F80 and P80 by analyzing the size fragmentation distribution generated using split-desktop 4.0 software. Based on the calculations used, the average value of the reduction ratio is 16.41 and the average value of the bond work input calculation is 0.36 kWh/ton. This study analyzes the effect of feed size and feed rate on the percentage of oversize and work input which of the two data does not have a relationship which will not affect the performance of the LSC VI crushing plant. In this study, it is also in accordance with the Kepmen standard No. 1827 K/30/MEM/2018 which applies both from the design of the hopper capacity and the percentage of oversize.

Abstrak. Batu gamping merupakan salah satu bahan baku utama dalam pembuatan semen. Pengolahan batu gamping untuk memenuhi spesifikasi sebagai bahan baku di PT. Semen Padang dilakukan di crushing plant, salah satunya di LSC VI. Tujuan dari penelitian ini yaitu menghitung nilai rata-rata. Reduction Ratio dan Work Input yang terdapat pada crushing plant, mengetahui pengaruh ukuran umpan terhadap persentase oversize dan daya energi listik di crushing plant, mengetahui pengaruh laju pengumpanan terhadap persentase oversize dan daya energi listrik di crushing plant serta menganalisis kinerja crushing plant berdasarkan Kepmen ESDM No 1827 K/30/MEM/2018 dari sisi kapasitas maksimum 95% dan jumlah oversize maksimum 15%. Nilai F80 dan P80 diestimasi dengan menganalisis distribusi fragmentasi ukuran yang dihasilkan menggunakan software Split Desktop 4.0. Berdasarkan hasil perhitungan diperoleh nilai rata-rata reduction ratio yaitu sebesar 16,41 serta rata-rata Bond Work Input sebesar 0,36 kWh/ton. Hasil penelitian belum menunjukkan pengaruh ukuran umpan dan laju pengumpanan terhadap persentase oversize dan Work Input sehingga tidak akan mempengaruhi kinerja dari crushing plant LSC VI. Kegiatan peremukan di LSC VI juga telah sesuai dengan standar Kepmen ESDM No. 1827 K/30/MEM/2018 baik dari sisi kapasitas hopper maupun persentase oversize.