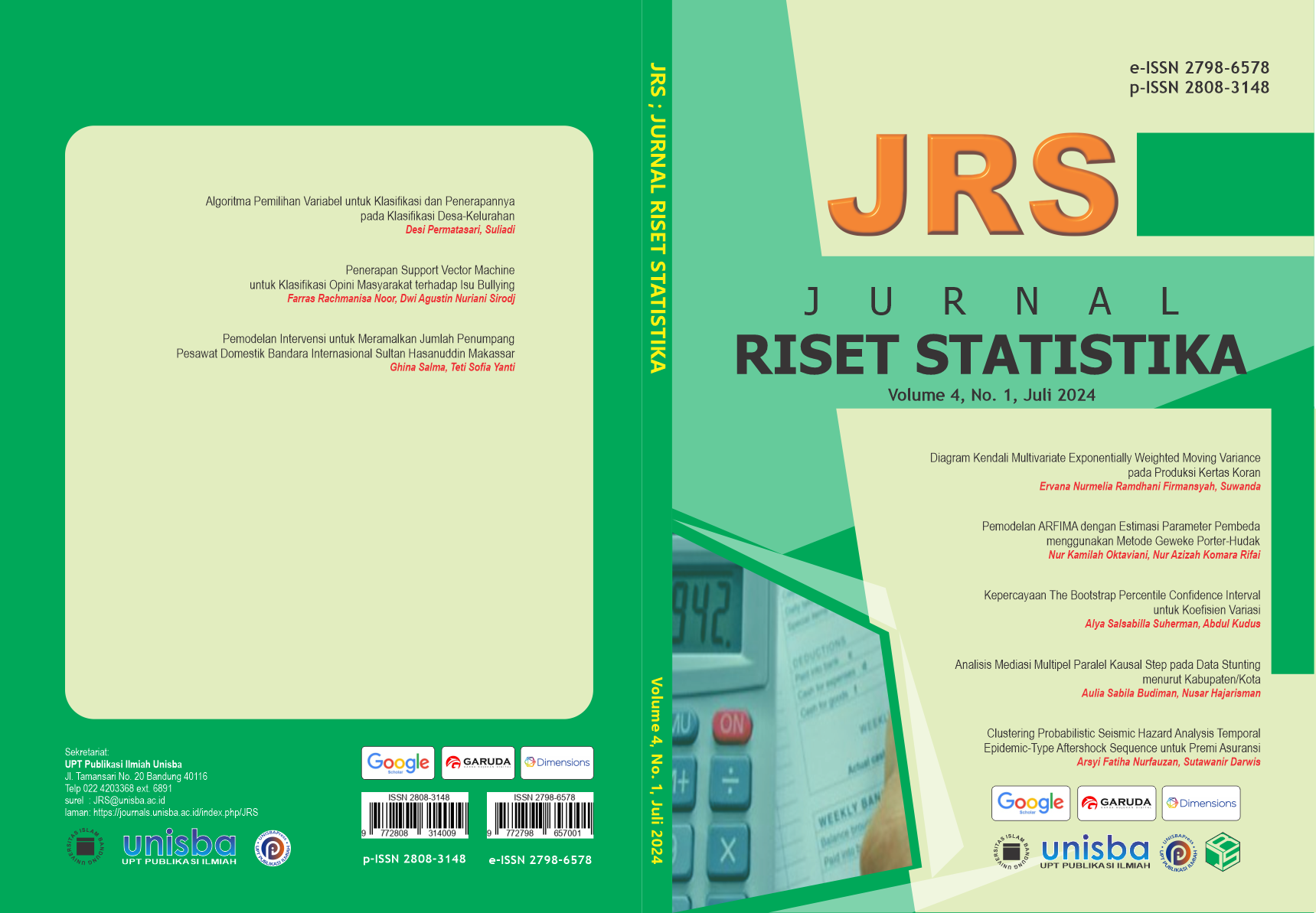

Diagram Kendali Multivariate Exponentially Weighted Moving Variance pada Produksi Kertas Koran

DOI:

https://doi.org/10.29313/jrs.v4i1.3834Keywords:

Pengendalian Kualitas Statistika Multivariat, Diagram Kendali MEWMV, Variabilitas ProsesAbstract

Abstract. In the multivariate process there are two parameters that must be controlled, namely the average vector and multivariate variability. During this time, the Generalize Variance control diagram, which requires a subgroup size (n) greater than the number of quality characteristics (p), is used to control the variability of multivariate processes. This study discusses the control diagram of multivariate process variability for a single subgroup size. The control diagram used is the Multivariate Exponentially Weighted Moving Variance (MEWMV) control chart. This MEWMV control diagram is implemented to control the production process of PRIMA 48.8 newspaper produced by PT. Adiprima Suraprinta (Jawa Pos Group). The results of the study found that to obtain a controlled process using a combination of weighting values each ω = 0.1; 0.5; 0.9 and λ = 0.1; 0.5; 0.9, 6 observation points were ignored and the remaining data were used as many as 30 observations. The simulated MEWMV control diagram was performed using data from the newly generated process with an average shift of 1.25sigma and 125% variance. The result shows that the weighting value ω = 0.1; λ = 0.1 simulated MEWMV diagram is more sensitive to shift variance in controlling the PRIMA 48.8 newsprint production process.

Abstrak. Pada proses multivariat terdapat dua parameter yang harus dikendalikan, yaitu vektor rata-rata dan variabilitas multivariat. Selama ini, diagram kendali Generalize Variance yang memerlukan ukuran subgroup (n) lebih besar daripada banyaknya karakteristik kualitas (p), digunakan untuk pengendalian variabilitas proses multivariat. Penelitian ini membahas diagram kendali variabilitas proses multivariat untuk ukuran subgroup tunggal. Diagram kendali yang digunakan adalah diagram kendali Multivariate Exponentially Weighted Moving Variance (MEWMV). Diagram

kendali MEWMV ini diimplementasikan untuk mengendalikan proses produksi koran PRIMA 48.8 yang diproduksi oleh PT. Adiprima Suraprinta (Jawa Pos Group). Hasil penelitian didapatkan bahwa untuk mendapatkan proses terkendali dengan menggunakan kombinasi nilai pembobot masing-masing

References

D. M. Hawkins and K. D. Zamba, “Statistical Process Control for Shifts in Mean or Variance Using a Changepoint Formulation,” Technometrics, vol. 47, no. 2, pp. 164–173, May 2005, doi: 10.1198/004017004000000644.

D. C. Montgomery, Introduction to Statistical Quality Control, Seventh Edition. United States of America: John Wiley & Sons, Inc, 2013.

M. Bernardino, “Penerapan CUSUM-Tukey’s Control Chart untuk Mendeteksi Perubahan Rata-Rata Proses pada Data Non-Normal,” Jurnal Riset Statistika, vol. 3, no. 2, pp. 119–124, Dec. 2023, doi: 10.29313/jrs.v3i2.2955.

S. M. Diyandini and E. Kurniati, “Analisis Maksimalisasi Utilitas Konsumen Melalui Grafik dan Persamaan Rumus,” DataMath: Journal of Statistics and Mathematics, vol. 2, no. 1, pp. 1–10, 2024.

A. B. Yeh, L. Huwang, and C. Wu, “A Multivariate EWMA Control Chart for Monitoring Process Variability with Individual Observations,” IIE Transactions , vol. 37, no. 11, pp. 1023–1035, 2005.

D. M. Hawkins and E. M. Maboudou-Tchao, “Multivariate Exponentially Weighted Moving Covariance Matrix,” Technometrics, vol. 50, no. 2, pp. 155–166, May 2008, doi: 10.1198/004017008000000163.

A. C. Rencher and W. F. Christensen, Methods of Multivariate Analysis, Third Edition. United States of America: John Wiley & Sons, Inc, 2012.

L. Huwang, A. B. Yeh, and C.-W. Wu, “Monitoring Multivariate Process Variability for Individual Observations,” Journal of Quality Technology, vol. 39, no. 3, pp. 258–278, Jul. 2007, doi: 10.1080/00224065.2007.11917692.

N. G. T. Gunaratne, M. A. Abdollahian, S. Huda, and J. Yearwood, “Exponentially Weighted Control Charts To Monitor Multivariate Process Variability For High Dimensions,” Int J Prod Res, vol. 55, no. 17, pp. 1–15, Sep. 2017, doi: 10.1080/00207543.2016.1278081.

“PT. Adiprima Suraprinta.” Accessed: Jan. 17, 2024. [Online]. Available: http://www.adiprima.com/

A. W. Widyasmara, “Pengendalian Kualitas Proses Produksi Kertas Koran PT. Adiprima Suraprinta Menggunakan Multivariat Hotelling T2,” Institut Teknologi Sepuluh Nopember, 2016.

K. V. Mardia, “Measures of Multivariate Skewness and Kurtosis with Applications,” Biometrika, vol. 57, no. 3, pp. 519–530, Dec. 1970, doi: 10.2307/2334770.